News

A2025-08-15

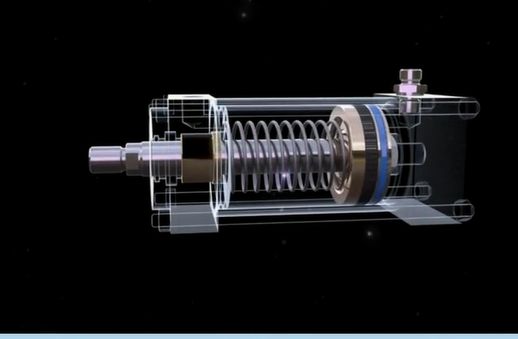

As the core component of cylinder sealing systems, piston seals undertake the critical task of pressure isolation. Their performance directly determines output efficiency, speed stability, energy consumption, and service life of cylinders. This article analyzes the system’s functions, seal composition, and failure impacts.

I. Core Functions

Establishing Pressure Differential:

Dividing the cylinder into two isolated chambers enables effective pressure separation. The stable pressure differential acts on the piston’s effective area to generate driving force. Seal failure causes air leakage, insufficient force, speed fluctuation (crawling), etc.

Withstanding Pressure & Wear:

Maintains sealing integrity under pressures ranging from several to hundreds of Bar while enduring severe friction from reciprocating motion.

Location:

Mounted in circumferential grooves on the piston’s outer periphery.

II. Key Seal Types & Functions

Wiper Seal (Scraper):

Location: Outermost position (right side)

Feature: Sharp scraping lip contacting the rod surface

Function: Scrapes contaminants (dust, debris, moisture) off the rod during retraction, acting as the primary barrier against internal component damage.

Material: Polyurethane (PU) or hard rubber (dark blue in figure)

Failure Impact: Accelerated internal wear, premature rod seal failure

Rod Seal (Primary Seal):

Location: Between wiper seal and guide ring/end cover (inner side)

Feature: U/Y-shaped profile with pressure-activated lip (black in figure)

Function:

Primary: Prevents leakage of pressure media (air/hydraulic fluid) along the rod

Low pressure: Sealing via elastic preload

High pressure: Pressure intensification forces lip against rod

Secondary: Limits contaminant ingress (minor role)

Material: PU, NBR, FKM, or composite seals (e.g., Stepseal)

Failure Impact: Pressure loss, efficiency decline, environmental contamination

III. Conclusion

Modern piston seals adopt elastomer + wear-resistant ring combinations (e.g., Glyd Ring, Stepseal). The preload at low pressure + pressure-energized sealing at high pressure efficiently isolates chamber pressure to convert differentials into linear thrust. Performance hinges on materials science, precision engineering, and proper maintenance. Optimal selection is paramount for cylinder reliability and operational efficiency.

[DLSEALS kindly Reminder] Sealing issues? Turn to DLSEALS! As a sealing component manufacturer, we specialize in customizing sealing components, providing a full range of services from design, research and development, production, testing, and more. If you have more information you'd like to know, feel free to contact us directly. DLSEALS's product experts are dedicated to serving you!