News

A2025-07-17

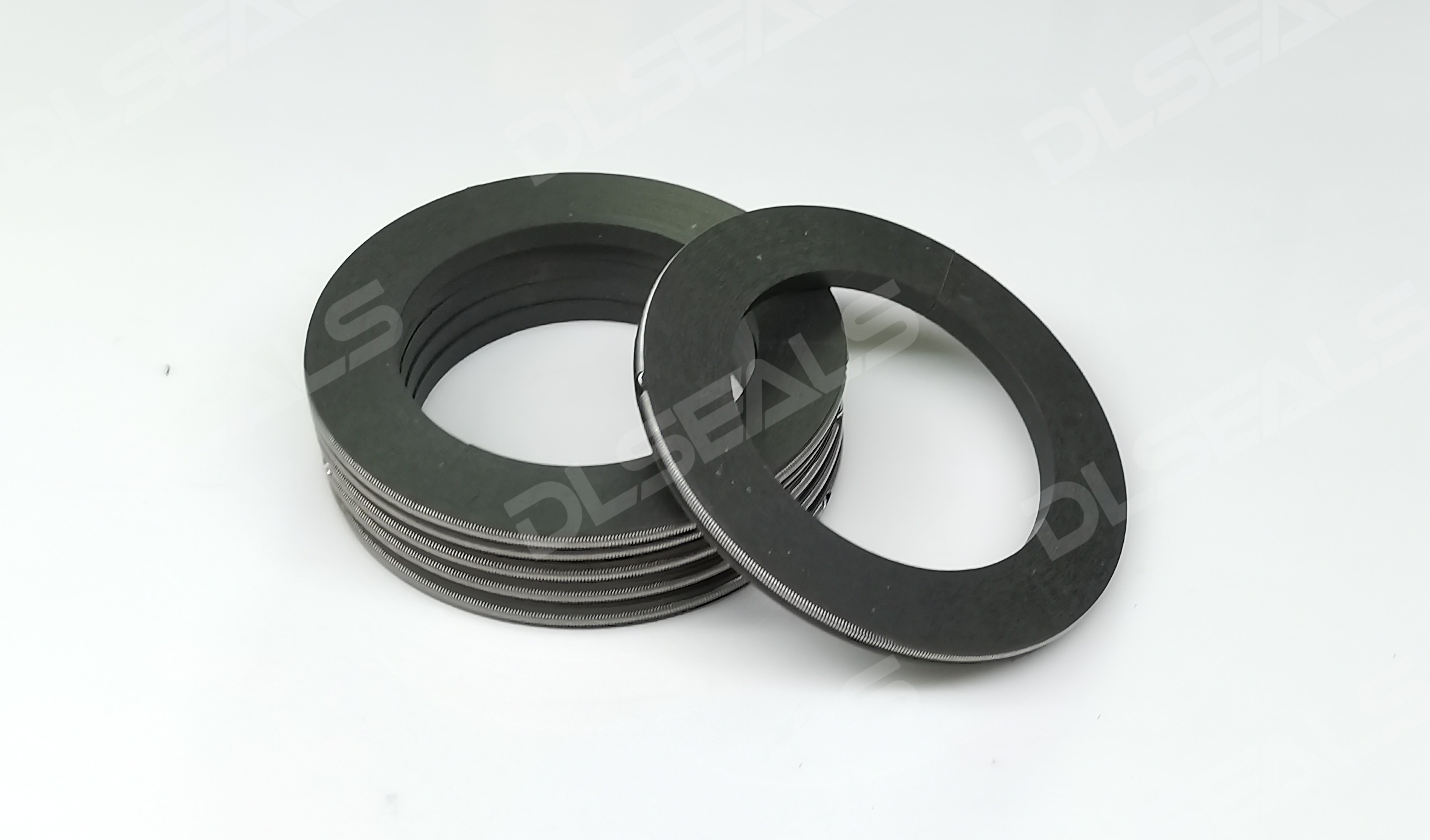

Oil Control Rings act as the "blood purifier" in reciprocating compressors, performing two critical tasks:

Extreme Condition Challenges:

| Property | Cast Iron + Chrome | Nano-PTFE Composite | Improvement |

|---|---|---|---|

| Friction Coefficient | 0.12–0.18 | 0.04–0.07 | ↓65% |

| Oil Film Control | ±2.5μm | ±0.8μm | ↑72% |

| Max. Temperature | 150°C (coating failure) | 260°C | ↑73% |

| Side Force Resistance | Requires >1.5mm thickness | 0.8mm thin-wall design | Weight ↓40% |

Material Innovations:

Asymmetric Dual-Edges:

Drainage Channels:

| Parameter | Traditional Ring | Nano-PTFE Ring | Benefit |

|---|---|---|---|

| Oil Consumption | 18g/h | 5g/h | Saves ¥67k/year* |

| Friction Power Loss | 8.2kW | 6.5kW | ↓21% energy |

| Oil Carryover | 0.8mg/m³ | 0.06mg/m³ | Class 0 compliant |

| Maintenance Interval | 4,000h | 12,000h | ↓65% labor cost |

8,000h/year operation; electricity ¥0.8/kWh; lubricant ¥150/kg

Failure Thresholds:

| Parameter | Normal Range | Replacement Limit | Inspection Method |

|---|---|---|---|

| Radial Clearance | 0.1–0.3mm | >0.6mm | Feeler gauge |

| Face Warping | ≤0.02mm | >0.1mm | Optical flat |

| Edge Radius (Ra) | 0.2μm | >1.6μm | Profilometer |

Installation:

Next-Gen Tech:

Advanced oil control systems redefine compressor efficiency frontiers, enabling near-zero-loss compression.

[DLSEALS kindly Reminder] Sealing issues? Turn to DLSEALS! As a sealing component manufacturer, we specialize in customizing sealing components, providing a full range of services from design, research and development, production, testing, and more. If you have more information you'd like to know, feel free to contact us directly. DLSEALS's product experts are dedicated to serving you!