News

A2024-06-19

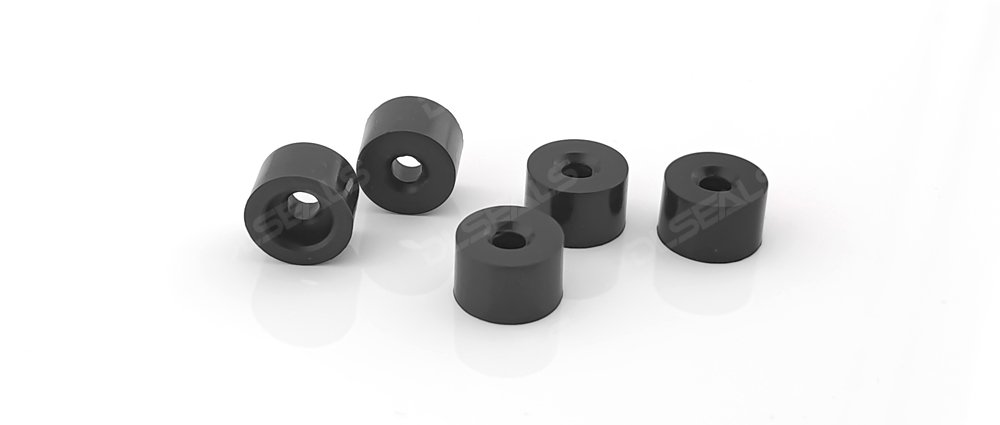

As a common sealing material, rubber seals play an important role in all walks of life. They use the elasticity and plasticity of rubber materials to seal the connection parts or equipment, prevent the leakage of fluids, gases or powders, and ensure the normal operation of the equipment. Let's take a look at the sealing principle and selection tips of rubber seals.

Sealing principle

The sealing principle of rubber seals is mainly to fill the gap of the connection parts through its elastic deformation to form a seal. When subjected to external pressure, the rubber seal will deform and exert pressure on the connection parts, so that the connection is well sealed. The effectiveness of the sealing principle depends on the elasticity, hardness and material properties of the rubber seal.

Material selection tips

Durability: Choose rubber materials with good wear resistance, aging resistance and corrosion resistance to ensure that the seals are not damaged during long-term use.

Temperature adaptability: Select suitable rubber materials according to the temperature range of the working environment to ensure that they still maintain good elasticity and sealing performance under high or low temperature conditions.

Medium compatibility: Understand the properties of the medium in the environment where the seal is located, and select rubber materials compatible with the medium to prevent the medium from corroding or expanding the seal.

Pressure requirements: Select the appropriate seal hardness and thickness according to the working pressure of the equipment to ensure effective sealing under high pressure.

Seal type: Select the appropriate rubber seal according to the type of seal (static seal or dynamic seal), shape and size requirements to ensure good cooperation with the equipment.

In summary, the sealing principle of rubber seals is based on its elastic deformation to achieve sealing, and choosing the right material is crucial. When selecting rubber seals, factors such as durability, temperature adaptability, media compatibility, pressure requirements and sealing type need to be considered to ensure the best sealing effect and ensure the safe operation of the equipment.

[DLSEALS kindly Reminder] Sealing issues? Turn to DLSEALS! As a sealing component manufacturer, we specialize in customizing sealing components, providing a full range of services from design, research and development, production, testing, and more. If you have more information you'd like to know, feel free to contact us directly. DLSEALS's product experts are dedicated to serving you!