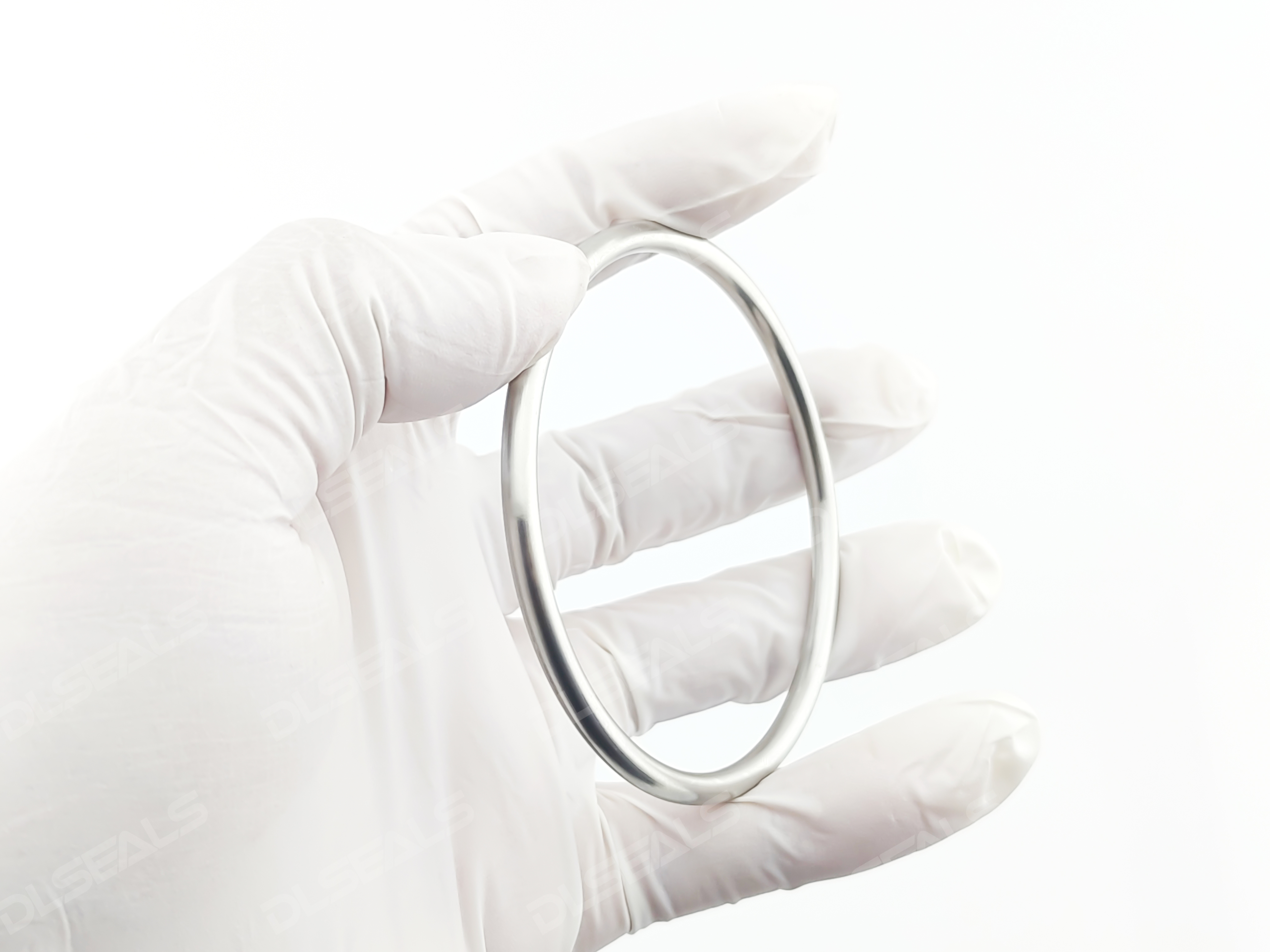

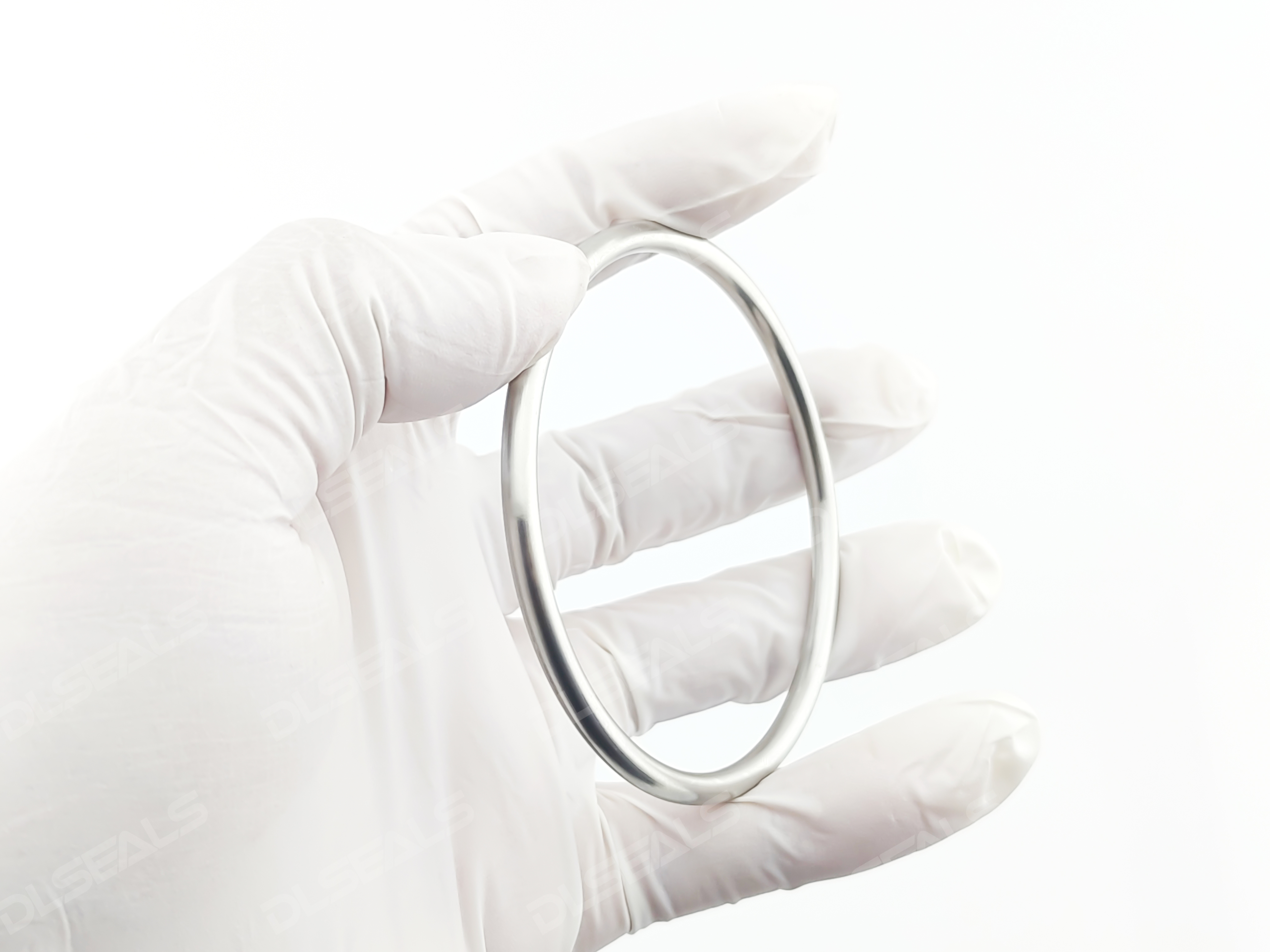

In harsh environments subjected to both cryogenic temperatures and ultra-high pressure—where the medium is liquid nitrogen (boiling point: -196°C), operating temperature drops to -200°C, and pressure reaches 20MPa (~200 atm)—the failure of any sealing component could trigger catastrophic consequences. For metal sealing rings with an inner diameter of 110mm and wire diameter of 3.2mm, the scientific selection of materials and structural design becomes critical.

I. Core Challenges in Extreme Conditions

- Low-Temperature Embrittlement Trap: At -200°C, the toughness of most materials plummets, while brittleness surges. Sealing rings risk catastrophic fracture due to stress concentration or minor impact.

- High-Pressure Deformation Threat: 20MPa pressure demands ultra-high yield strength and anti-deformation rigidity to prevent failure caused by excessive compression, extrusion (from flange gaps), or structural instability.

- Thermal Contraction Mismatch Risk: Differences in thermal expansion coefficients (CTE) between sealing ring materials (e.g., stainless steel) and flange materials can cause seal contact loss, pressure leakage, or localized stress overload.

- Liquid Nitrogen Compatibility: Despite liquid nitrogen’s chemical inertness, sealing materials must remain fully stable at -200°C, eliminating risks of embrittlement, phase transitions, or decomposition.

- Sealing Maintenance Capability: Materials require moderate plastic flow ("cold flow") to fill microscopic flange defects and achieve initial sealing. They must retain sufficient elastic recovery to handle pressure fluctuations or thermal cycles.

II. Primary Recommendations: Austenitic Stainless Steel & Specialty Alloys

Considering performance balance, cost-effectiveness, and supply chain maturity, the following materials are prioritized for 110×3.2mm rings under -200°C/20MPa:

-

Enhanced Austenitic Stainless Steel (Primary Choice):

- Grades: 304L / 316L. Ultra-low carbon content minimizes carbide precipitation risk during welding or thermal cycling, ensuring cryogenic toughness. Excellent resistance to embrittlement, good machinability, and liquid nitrogen compatibility make them optimal. 304L strength suffices at 20MPa; upgrade to Mo-containing 316L if traces of corrosive impurities exist.

- Key Advantages: Industry maturity, cost control, superior cryogenic toughness (Charpy V-notch impact >100J at -196°C).

- State Recommendation: Solution-annealed cold-drawn wire with cryogenic treatment and precision grinding.

-

Aluminum Bronze (Critical Alternative):

- Grades: C95400 (CuAl10Fe3) / C95500 (CuAl11Fe6Ni6).

- Key Advantages: Unmatched cryogenic toughness (retains ductility down to -269°C), high strength/hardness to resist extrusion/wear, excellent cold flow for sealing surface conformity, and better thermal conductivity than stainless steel.

- Considerations: Ideal for dynamic friction/frequent disassembly. Low risk in pure liquid nitrogen but assess potential oxygen compatibility. Higher cost than stainless steel.

-

Nickel-Based Alloys (High-Performance Backup):

- Grades: Inconel 718 (high strength), Hastelloy C-276/C-22 (corrosion resistance).

- Benefits: Inconel 718 offers ductility at -253°C plus ultra-high strength (>20MPa). Hastelloy excels in corrosive impurities (e.g., acids, Cl⁻ ions).

- Limitations: High cost and manufacturing complexity; reserved for extreme pressures/corrosion risks.

Critical Material: Performance Data for 304L at -200°C

| Property |

304L Austenitic Stainless Steel (-200°C) |

Significance |

| Tensile Strength (Rm) |

≈ 1500 MPa |

Doubles vs. RT; withstands 20MPa |

| Fracture Toughness (K_IC) |

120-180 MPa·√m |

Prevents brittle fracture |

| CTE (α) |

10.5 ×10⁻⁶/K |

Match with flange CTE |

| Thermal Conductivity (λ) |

≈ 9 W/(m·K) |

Improves thermal distribution |

III. Structural Optimization for 110×3.2mm Rings

- Wire Diameter Analysis: 3.2mm wire diameter (vs. 110mm ID) provides sufficient cross-section to resist 20MPa pressure and deformation. Thinner wires would collapse.

- Preferred Seal Designs:

- C-Ring: Simple C-shaped cross-section. Moderate compression (15–25% wire diameter). Reliable up to 70MPa+. Lower cost, ideal for static seals.

- E-Ring: Inverted E-shaped cross-section (dual sealing lines). Better resilience for thermal cycling/vibration. Higher tolerance to flange misalignment.

- Surface Enhancement: Seal surfaces must achieve mirror finish (Ra ≤ 0.8µm, ideally ≤0.4µm). Apply thin silver plating (<5µm) to enhance thermal contact/cryogenic sealing.

IV. Manufacturing, Installation & Quality Control

- Material Sourcing: Traceable cryogenic-certified wire (e.g., ASTM A276/A479). Control P≤0.015%, S≤0.003%.

- Precision Manufacturing:

- Stress-controlled cold forming + stress-relief annealing.

- Welding: High-purity Ar TIG + 100% RT inspection + cryo-cycling.

- Dimensional accuracy: ±0.02mm diameter, ovality ≤0.03mm.

- Surface Finishing: Final electrolytic/chemical polishing to remove micro-cracks (Ra ≤0.4µm).

- Installation Protocol:

- Flange requirements: Ra ≤1.6µm, parallelism ≤0.05mm.

- Bolt Pre-tension: Use calibrated hydraulic tensioners. Apply cryogenic compensation to preload. Never impact-tighten!

- Cooling Protocol: Ramp cooling ≤5°C/min to avoid thermal shock.

V. Conclusion

For liquid nitrogen at -200°C/20MPa, cryo-treated 304L/316L stainless steel offers optimal toughness, strength, and cost-efficiency for Ø110×3.2mm seals. Aluminum bronze (C95500) excels in wear/frequent-maintenance scenarios, while nickel alloys (Inconel 718/Hastelloy) address extreme pressure/corrosion.

Ultimate reliability hinges on:

- Impeccable material sourcing

- Precision manufacturing (especially surface finish)

- Strict installation discipline.

[DLSEALS kindly Reminder] Sealing issues? Turn to DLSEALS! As a sealing component manufacturer, we specialize in customizing sealing components, providing a full range of services from design, research and development, production, testing, and more. If you have more information you'd like to know, feel free to contact us directly. DLSEALS's product experts are dedicated to serving you!