News

A2024-07-20

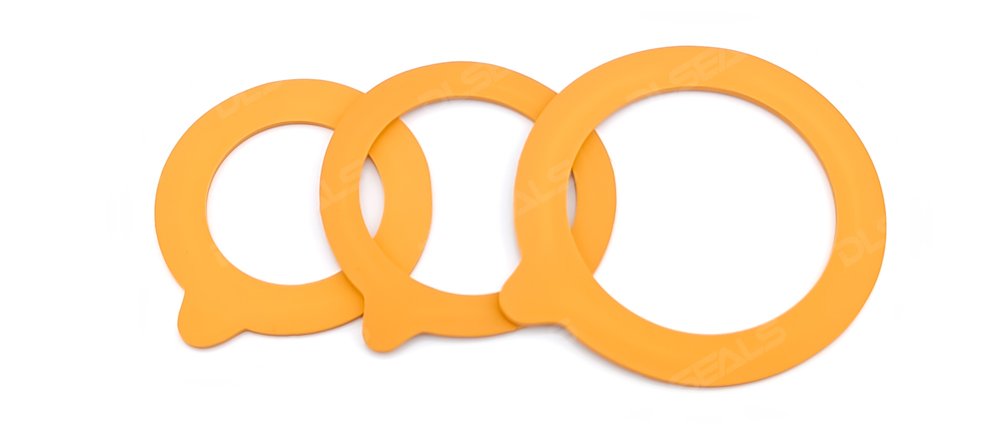

In the food industry, safety is of vital importance. As an important component of food processing equipment, the compliance of rubber seals is crucial to ensure food safety. This article will analyze the compliance of rubber seals and explore their importance in the food industry.

1. Uses of rubber seals

Rubber seals are widely used in food processing equipment to seal containers, pipes and other components to ensure that food is not contaminated by the outside world during processing, transportation and storage. Its sealing performance directly affects the quality and safety of food.

2. Compliance requirements of rubber seals

Food grade materials: Rubber seals must be made of raw materials that meet food grade safety standards to ensure that no harmful substances are released and no food is contaminated.

Corrosion resistance: Seals need to have good corrosion resistance and be able to remain stable when in contact with various foods without deterioration or dissolution.

Temperature and pressure adaptability: Seals need to be able to adapt to working environments under different temperature and pressure conditions to ensure good sealing performance under various process conditions.

Compliance certification: The production of rubber seals must comply with relevant laws, regulations and standards, and must be certified by authoritative organizations, such as FDA (U.S. Food and Drug Administration) certification, EU CE certification, etc.

3. The importance of rubber seals

The compliance of rubber seals is directly related to the safety of food processing equipment and the quality of food. Rubber seals that meet safety requirements can effectively prevent food contamination and cross-infection and protect the health of consumers. In addition, compliant seals can also improve production efficiency, reduce failures and downtime in production, reduce production costs, and enhance corporate competitiveness.

In summary, the compliance of rubber seals in the food industry is crucial. Enterprises should strengthen the selection and management of rubber seals to ensure that they meet relevant safety standards and requirements to ensure food safety and long-term development of enterprises.

[DLSEALS kindly Reminder] Sealing issues? Turn to DLSEALS! As a sealing component manufacturer, we specialize in customizing sealing components, providing a full range of services from design, research and development, production, testing, and more. If you have more information you'd like to know, feel free to contact us directly. DLSEALS's product experts are dedicated to serving you!