News

A2024-12-14

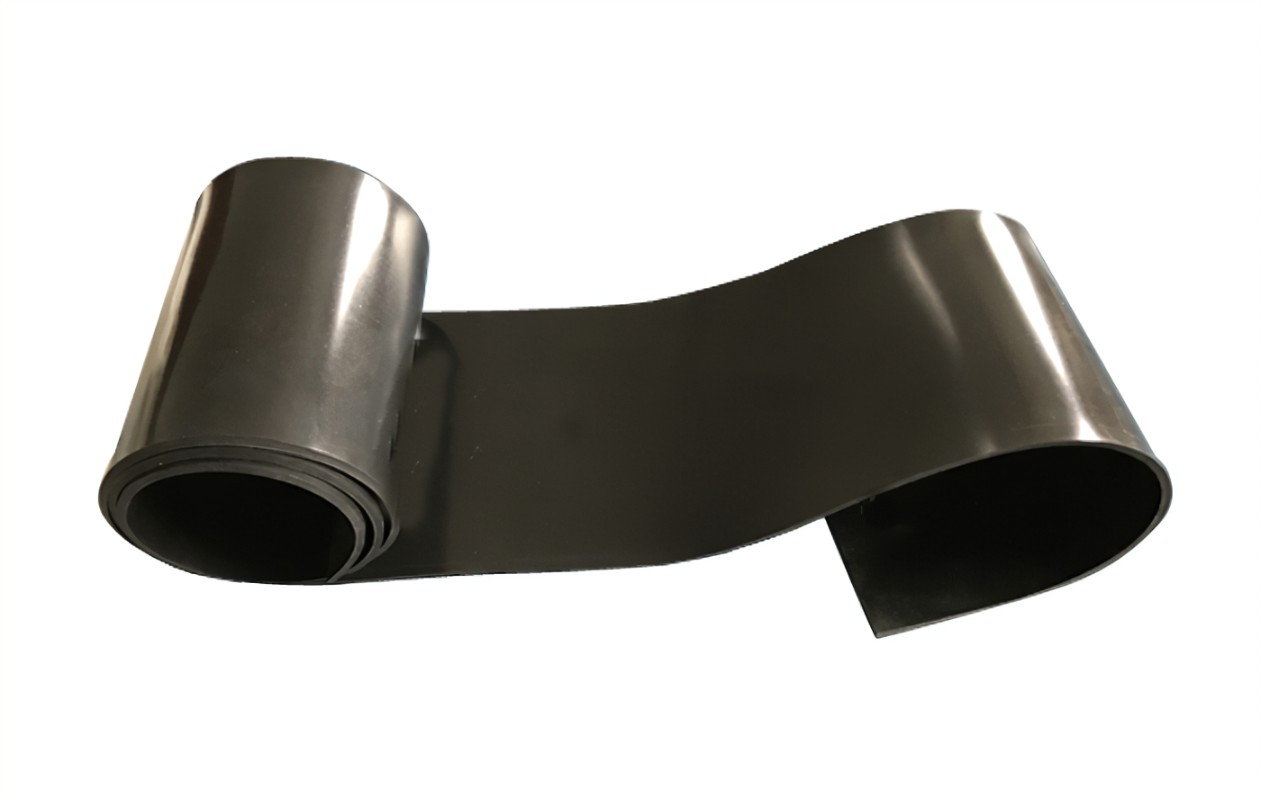

Flame retardant rubber is a rubber material with special properties. It can slow down the burning speed or even prevent burning completely when it comes into contact with fire, thus providing additional safety protection. With the improvement of people's safety awareness and the increase of fire protection requirements, flame retardant rubber has been widely used in many industries, such as the automotive industry, electronics industry, construction industry, etc. This article will discuss the types, preparation methods, flame retardant mechanisms and applications of flame retardant rubber in different fields.

1. Types of flame retardant rubber

Flame retardant rubber can be classified according to its base material and flame retardant.

Classification by base material:

Natural rubber (NR)

Styrene-butadiene rubber (SBR)

Butadiene rubber (BR)

Chloroprene rubber (CR)

Nitrile rubber (NBR)

Fluororubber (FKM)

Classification by flame retardant:

Halogen-containing flame retardants (such as chlorinated polyethylene, tetrabromobisphenol A)

Inorganic flame retardants (such as aluminum hydroxide, magnesium hydroxide)

Phosphorus-based flame retardants (such as red phosphorus, phosphate esters)

Nitrogen-based flame retardants (such as melamine)

2. Preparation of flame-retardant rubber

The preparation of flame-retardant rubber usually involves mixing the flame retardant with the rubber base, followed by mixing, molding and vulcanization.

Mixing: The rubber base is fully mixed with the flame retardant and other additives (such as vulcanizers, accelerators, fillers) in a mixer to ensure that the flame retardant is evenly dispersed in the rubber.

Molding: The mixed rubber material is molded into the desired shape by calendering, extrusion or injection.

Vulcanization: By heating, the rubber molecules undergo cross-linking reactions to form a three-dimensional network structure, thereby obtaining the required physical and mechanical properties and flame retardant properties.

3. Flame retardant mechanism

The flame retardant properties of flame retardant rubber are mainly achieved through the following mechanisms:

Endothermic effect: Some flame retardants (such as aluminum hydroxide and magnesium hydroxide) decompose and absorb a large amount of heat energy when heated, thereby reducing the temperature of the material and delaying the combustion process.

Covering effect: The non-volatile substances produced by the decomposition of flame retardants will form an isolation layer on the rubber surface, isolating oxygen and heat sources and preventing further combustion.

Inhibition of chain reactions: Some flame retardants can capture free radicals and interrupt the chain reaction of combustion, thereby achieving a flame retardant effect.

Release of non-flammable gases: Some flame retardants release non-flammable gases such as carbon dioxide and water vapor when decomposed. These gases can dilute the concentration of combustible gases and inhibit combustion.

4. Application fields

Flame-retardant rubber is used in many fields due to its excellent flame-retardant properties:

Automotive industry: used to manufacture wire and cable sheaths, seals, shock absorbers, etc. to meet the fire protection requirements of automobile interiors.

Electronic industry: used for cables, connectors and housings of electronic equipment to prevent electrical fires.

Construction industry: used for sealing materials, floor materials and sound insulation materials in buildings to improve the fire resistance of buildings.

Aviation and rail transportation: flame-retardant rubber products are used inside airplanes and trains to improve the safety of transportation vehicles.

5. Development trend

With the advancement of science and technology and the improvement of environmental protection requirements, the development trend of flame-retardant rubber is mainly reflected in:

Development of environmentally friendly flame retardants: reduce the use of halogen-containing flame retardants, and develop non-toxic, low-smoke, and low-toxic environmentally friendly flame retardants.

Development of high-performance flame-retardant rubber: prepare rubber materials with higher flame retardant properties and better physical and mechanical properties by improving the dispersion technology of flame retardants and improving flame retardant efficiency.

Multifunctional integration: Combining flame retardancy, anti-aging, weather resistance and other properties, develop multifunctional integrated flame retardant rubber materials.

Conclusion

As an important functional material, flame retardant rubber plays an important role in protecting people's lives and property. By selecting suitable matrix materials and flame retardants, and optimizing the preparation process, flame retardant rubber products with excellent performance can be obtained. In the future, with the continuous emergence of new materials and new technologies, flame retardant rubber will show its unique value in more fields.

[DLSEALS kindly Reminder] Sealing issues? Turn to DLSEALS! As a sealing component manufacturer, we specialize in customizing sealing components, providing a full range of services from design, research and development, production, testing, and more. If you have more information you'd like to know, feel free to contact us directly. DLSEALS's product experts are dedicated to serving you!