News

A2024-09-13

Sealing rings working in high temperature environments are not only subject to extreme thermal stress, but may also be affected by chemical corrosion, wear, thermal aging and other factors. In order to ensure the long-term reliability of sealing rings under high temperature conditions, material selection and design are crucial. The following will discuss how to select suitable sealing materials and ensure their long-term reliability in high temperature environments from several key perspectives.

1. Material high temperature resistance

One of the biggest challenges for sealing materials in high temperature environments is thermal stability. Materials will undergo softening, expansion, chemical structure changes, and even decomposition at high temperatures. Therefore, ensuring that the physical and chemical properties of materials remain stable at high temperatures is the basis for the long-term reliability of sealing rings.

Material thermal decomposition temperature: When selecting materials, it is necessary to ensure that their thermal decomposition temperature is much higher than the operating temperature. For example, the thermal decomposition temperature of fluororubber (FKM) can reach 250°C to 300°C, while the thermal decomposition temperature of PTFE is close to 300°C. These materials can maintain relatively stable performance at high temperatures.

Material thermal expansion coefficient: At high temperatures, the sealing ring material will undergo dimensional changes due to thermal expansion. Selecting materials with a low thermal expansion coefficient helps reduce the impact of this dimensional change on sealing performance. For example, PTFE has a low coefficient of thermal expansion and is suitable for use in high-temperature applications.

2. Anti-oxidation and anti-thermal aging performance

In high-temperature environments, the oxidation reaction rate of materials will accelerate, resulting in aging, hardening or embrittlement. This aging will significantly reduce the elasticity and flexibility of the seal ring, resulting in seal failure. Therefore, anti-oxidation and anti-thermal aging performance are the top priorities when selecting high-temperature sealing materials.

Material oxidation resistance: Some materials show strong oxidation resistance at high temperatures and can effectively delay aging. For example, fluororubber (FKM) and silicone rubber (VMQ) have excellent oxidation resistance and can remain stable for a long time in high-temperature environments.

Anti-thermal aging additives: Adding an appropriate amount of anti-thermal aging agent to the sealing material can significantly extend the service life of the material. Common antioxidants, stabilizers and ultraviolet absorbers can effectively slow down the degradation rate of the material.

3. Chemical corrosion resistance

In high-temperature environments, the seal ring may be exposed to various chemical media, such as oils, acid and alkali solutions or organic solvents. If the chemical stability of the material is poor, it is easily corroded by these media, causing the material to swell, soften or deteriorate. Therefore, chemical corrosion resistance is also a key factor in ensuring long-term reliability.

Select materials with strong chemical resistance: PTFE is one of the most chemically stable materials. It is almost unaffected by any chemical medium and can be used for a long time in corrosive media such as acids, alkalis and organic solvents. Fluororubber also performs well in dealing with fuel and oil media.

Use of composite materials: In some extreme working conditions, a single material may not be able to meet all requirements at the same time. At this time, composite materials become an effective solution. For example, the combination of PTFE and metal skeleton can improve its mechanical properties under high temperature, high pressure and corrosive environment.

IV. Mechanical strength and creep resistance

High temperature environment not only affects the chemical stability of the material, but also causes its mechanical properties to deteriorate. Materials under high temperature conditions tend to creep, that is, under continuous high temperature and pressure, the material will gradually deform, and eventually lead to seal failure. Therefore, it is crucial to select materials with high mechanical strength and creep resistance.

Improve the mechanical strength of materials: Stress at high temperature usually leads to increased fluidity of the material, especially for elastomeric materials. The ability to resist compression and deformation can be improved by selecting materials with higher hardness or adding reinforcing fillers (such as graphite and glass fiber) to the material.

Creep-resistant materials: PTFE has excellent creep resistance and is often used in applications that require long-term exposure to high temperatures and high pressures. Hydrogenated nitrile rubber (HNBR) also performs well under high temperature and high pressure conditions.

V. Sealing design and structural optimization

Although the selection of materials is the key to ensuring the long-term reliability of the seal ring in a high temperature environment, reasonable design and structural optimization are equally important. By optimizing the shape, size and sealing method of the seal ring, the impact of thermal and mechanical stress on the seal ring can be effectively reduced and its service life can be extended.

Consider thermal expansion and contraction: When designing, it is necessary to consider the thermal expansion of the material at high temperature and the contraction after cooling to ensure that the size and structure of the seal ring can adapt to temperature changes. At the same time, avoid excessive compression or excessive relaxation to prevent affecting the sealing performance.

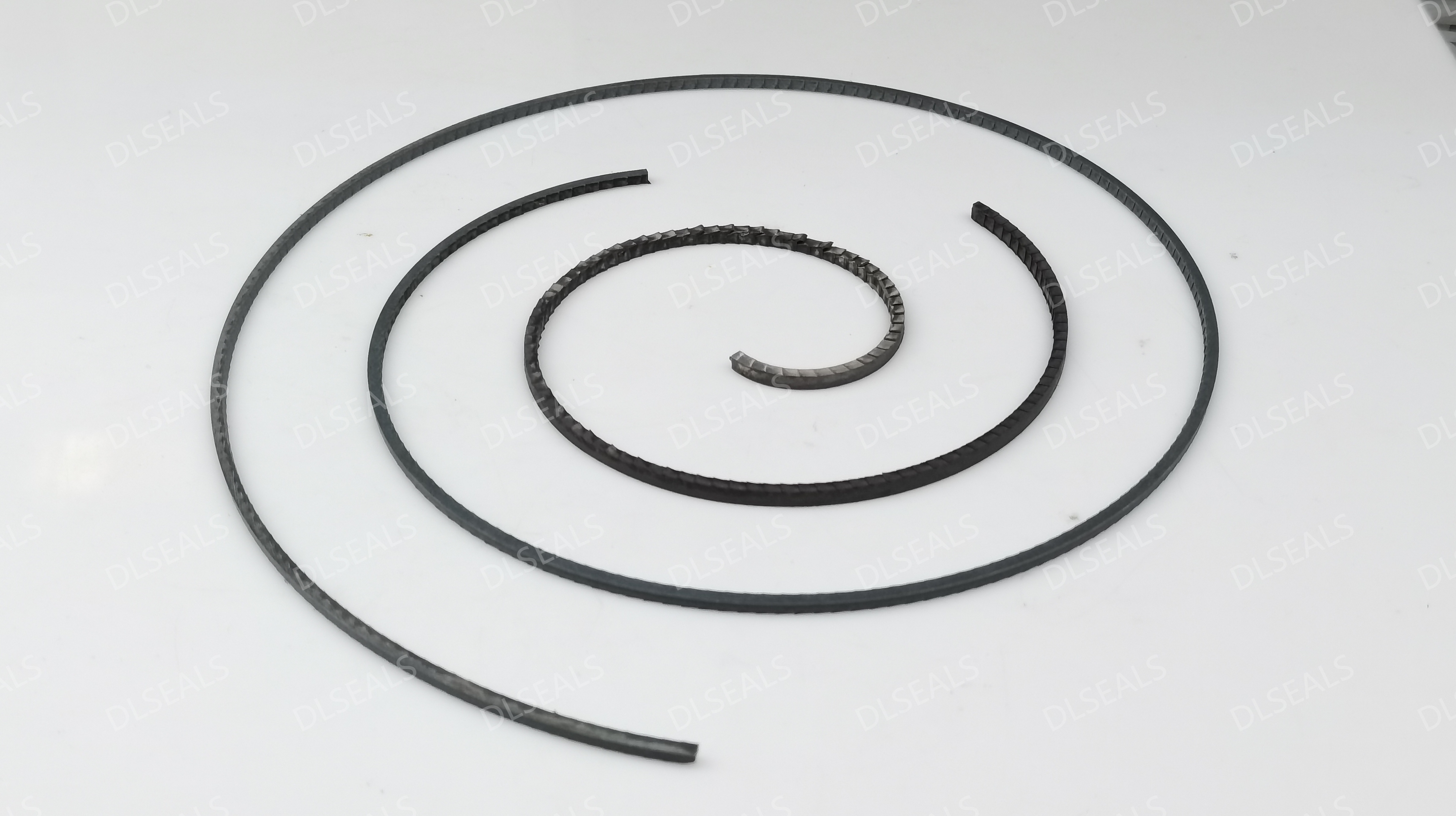

Choose a suitable sealing structure: O-rings and X-rings are common sealing structures, but under high temperature and high pressure conditions, choosing a composite sealing structure or using a metal-reinforced seal ring can effectively improve the stability and reliability of the seal.

VI. Regular maintenance and monitoring

Even if high-quality sealing materials and optimized designs are selected, long-term reliability still needs to be guaranteed through regular maintenance and monitoring. The seal ring in high temperature environment should be regularly checked for surface wear, aging and sealing effect. If any abnormality is found, it needs to be replaced or repaired in time to avoid equipment damage or leakage accidents.

Conclusion

To ensure the long-term reliability of the seal ring in high temperature environment, comprehensive considerations need to be made in terms of material selection, design optimization, and maintenance. Selecting materials with good thermal stability, oxidation resistance, chemical corrosion resistance and high mechanical strength, such as fluororubber, PTFE, HNBR, etc., can effectively cope with the challenges brought by high temperature. In addition, the stability and service life of the seal ring in high temperature environment can be further improved through structural design optimization and regular monitoring and maintenance.

[DLSEALS kindly Reminder] Sealing issues? Turn to DLSEALS! As a sealing component manufacturer, we specialize in customizing sealing components, providing a full range of services from design, research and development, production, testing, and more. If you have more information you'd like to know, feel free to contact us directly. DLSEALS's product experts are dedicated to serving you!