News

A2025-11-17

In complex industrial equipment and precision machinery, sealing systems act as "unsung heroes," whose performance directly impacts the reliability, efficiency, and service life of the equipment. Traditional seals, often with a single structure, can be inadequate when facing multiple challenges. An innovative design—the multi-limb seal—with its unique fork-like multi-limb structure, demonstrates the great potential of cooperative sealing technology, achieving a comprehensive improvement in sealing effectiveness.

This article will use its technical schematic as a core reference for an in-depth analysis of the intricacies of this design.

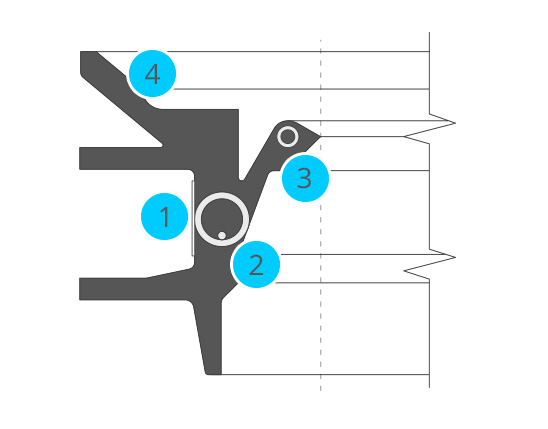

As shown in the schematic, the core feature of this seal is its multiple flat branches (limbs) formed as a single unit. This design fundamentally breaks away from the linear thinking of traditional O-rings or single-lip seals, establishing a multi-level, multi-stage cooperative sealing system. We can understand its operating principle through four key points marked on the diagram:

Primary Sealing Zone (Point 1 and Main Body Area):This is the first line of defense and the pressure-bearing core. The large vertical main body structure provides powerful initial sealing force, effectively blocking the passage of most media (such as lubricating oil, hydraulic fluid, or contaminants), establishing the primary sealing barrier.

Dynamic Compensation Limbs (Point 2 and Extending Limbs):These branches extending to the upper left are the essence of the design. They are flexible and pliable, like dexterous fingers. When system pressure fluctuates or components develop minute clearances due to wear or thermal expansion/contraction, these "limbs" can elastically deform, continuously pressing against the mating surface to dynamically compensate for gap changes. This ensures long-term sealing stability and effectively addresses leakage issues caused by wear in traditional seals.

Dust Protection and Secondary Sealing Limbs (Point 3 and Adjacent Branches):Branches located further outward can be designed to address specific challenges. For instance, the outermost "limb" can specialize in preventing the ingress of external pollutants like dust and moisture, acting as a wiper and auxiliary seal, thus protecting internal mechanical components.

Installation and Positioning Structure (Point 4 and Rear Contour):The serrated profile and parallel lines at the rear of the seal indicate a precision mating groove design. This ensures the seal is firmly fixed after installation, preventing distortion or displacement during operation, which is fundamental to ensuring all sealing limbs function correctly.

This multi-limb cooperative design offers several significant advantages:

Exceptional Sealing Reliability:Multiple sealing lines create a "stepped" defense, significantly reducing the risk of leakage. Even if one sealing line weakens slightly, subsequent limbs can still perform.

Superior Environmental Adaptability:Offers greater tolerance to pressure fluctuations, temperature variations, and mechanical vibrations. Its dynamic compensation ability allows it to maintain excellent performance even under harsh conditions.

Long Service Life:By distributing pressure and wear across multiple contact points, it avoids rapid aging in any single area, significantly extending the seal's replacement cycle and reducing maintenance costs.

Space Optimization:Within a limited installation space, a single component achieves what previously might have required multiple stacked seals, simplifying structural design.

This innovative multi-limb seal is ideally suited for applications with extremely high sealing demands, such as:

High-performance hydraulic systems(construction machinery, injection molding machines)

Precision transmission systems(aerospace actuators, robotic joints)

Rotating equipment in harsh environments(food processing, chemical pumps and valves)

Key components of new energy vehicles(motors, reducers)

In summary, the multi-limb seal shown in the schematic is not just an innovation of a single part; it represents a new philosophy in seal design—shifting from passive sealing to active adaptation, from single-point contact to coordinated operation. With its ingenious, almost biomimetic, multi-limb structure, it elevates sealing reliability, adaptability, and lifespan to a new level. It provides crucial foundational component support for the development of future high-end equipment, undoubtedly representing a significant step forward in industrial sealing technology.

[DLSEALS kindly Reminder] Sealing issues? Turn to DLSEALS! As a sealing component manufacturer, we specialize in customizing sealing components, providing a full range of services from design, research and development, production, testing, and more. If you have more information you'd like to know, feel free to contact us directly. DLSEALS's product experts are dedicated to serving you!