News

A2024-08-13

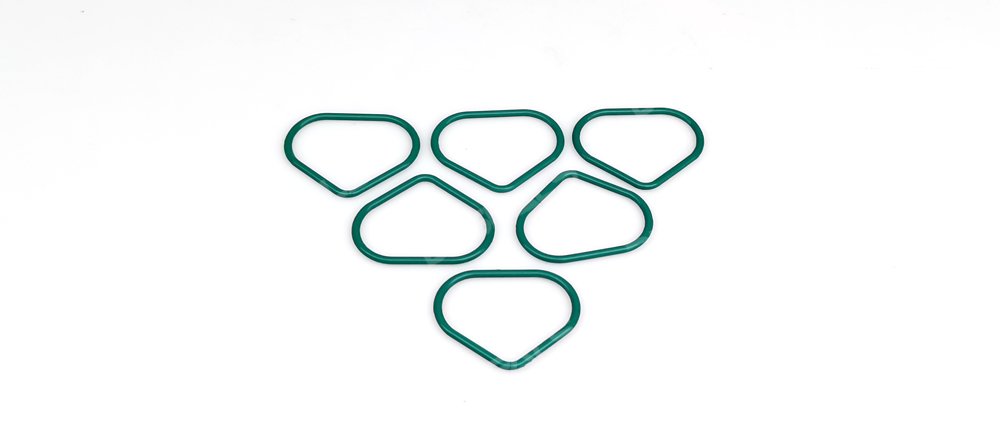

As a high-performance sealing material, fluororubber sealing rings exhibit excellent performance and reliability in high-temperature environments and are widely used in various types of industrial equipment and machinery. This article will discuss in detail the characteristics, advantages and applicable scenarios of fluororubber sealing rings in high temperature environments to help readers fully understand and choose appropriate sealing materials.

Characteristics and advantages of fluorine rubber

Fluorine rubber (FKM) is an excellent synthetic rubber material with the following significant characteristics and advantages:

Excellent high temperature resistance: Fluorine rubber sealing rings can work stably for a long time in high temperature environments. They can usually withstand operating temperatures above 200 degrees Celsius, or even up to 300 degrees Celsius, which is suitable for sealing needs under high temperature conditions.

Excellent chemical resistance: Fluorine rubber has excellent chemical resistance and can resist the erosion of a variety of chemical media, including oils, solvents, acids and bases, etc., maintaining stable physical and chemical properties.

Excellent aging resistance and weather resistance: Fluorine rubber sealing rings have a long service life, are not easily hardened, embrittled or aged due to environmental factors, and can maintain good elasticity and sealing effects for a long time.

Good mechanical properties: Fluorine rubber sealing rings have excellent mechanical strength and wear resistance, can withstand mechanical movement and pressure, and maintain stable sealing performance.

Applicable scenarios for fluororubber seals

Based on the excellent properties of fluororubber, it has a wide range of applications in the following high temperature environments:

Automotive industry: In sealing applications in high-temperature environments such as automobile engines, gearboxes, and hydraulic systems, fluororubber sealing rings can effectively prevent oil leakage and seal failure.

Chemical industry: In applications such as chemical production equipment, pipeline connections, and valve seals, fluororubber sealing rings can withstand the challenges of various chemical media and high-temperature environments to ensure safe operation of equipment.

Aerospace: In key components such as aero engines, aviation oil seals and hydraulic systems, fluororubber seals can maintain stable performance under extreme high temperature conditions to ensure the safety and reliability of aircraft.

Energy field: In oil and natural gas extraction, transmission pipelines, heat exchangers and other equipment, fluororubber sealing rings can withstand high temperatures and chemical corrosion, ensuring the long-term operation of energy facilities.

Conclusion

Generally speaking, fluororubber sealing rings perform excellently in various high temperatures and harsh working environments due to their excellent high temperature resistance, excellent chemical resistance and long-term stable mechanical properties. When selecting a fluororubber seal, the specific operating temperature, medium characteristics and sealing requirements need to be considered to ensure the best sealing effect and safe operation of the equipment. Correct material selection can not only improve the performance and efficiency of equipment, but also effectively reduce maintenance costs and equipment failure rates, making it an ideal choice for engineers and manufacturers.

[DLSEALS kindly Reminder] Sealing issues? Turn to DLSEALS! As a sealing component manufacturer, we specialize in customizing sealing components, providing a full range of services from design, research and development, production, testing, and more. If you have more information you'd like to know, feel free to contact us directly. DLSEALS's product experts are dedicated to serving you!